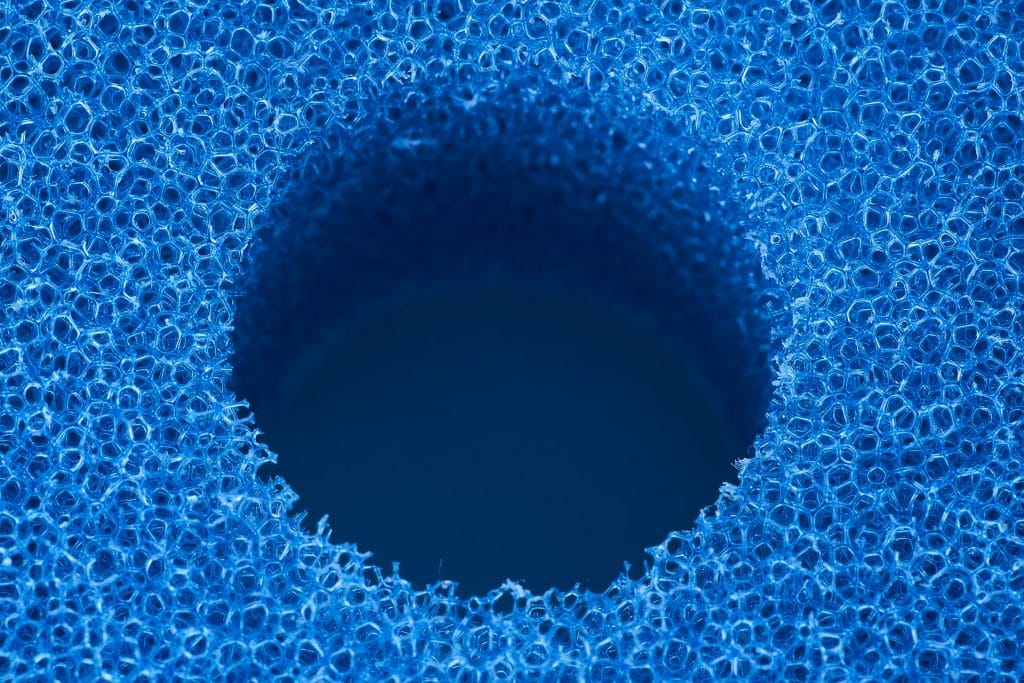

Wirft man einen Blick durch ein Mikroskop und sieht sich einen Polierschwamm im Detail an, erkennt man gut die Struktur des Schaumstoffes, die durch das „Retikulieren“ entstanden ist. Bei diesem Vorgang werden die bei der Produktion entstehenden dünnen „Häutchen“ zwischen den einzelnen Schaumstoffzellen gezielt zerstört.

Dazu wird ein Gemisch aus gasförmigen, brennbaren Stoffen (z. B. Knallgas) gleichzeitig mit dem Zündimpuls mit ca. + 185 °C heißem Wasserdampf (unter Druck) vermengt. Die explosiv freiwerdende Reaktionswärme sorgt für die Perforierung der Schaumstoff-Zellwände

Das Verfahren wurde in der Kunststofftechnik 1965 von der Firma Scott Paper & Co in den USA patentiert.

Durch das Retikulieren werden unsere Polierpads flüssigkeits- und luft- bzw. gasdurchlässig gemacht.